GNPower Mariveles Energy Center Ltd. Co (GMEC) commended the Boiler and Workshop Maintenance team with a Group Excellence Award for the month of November after generating more than 13 million pesos worth of savings.

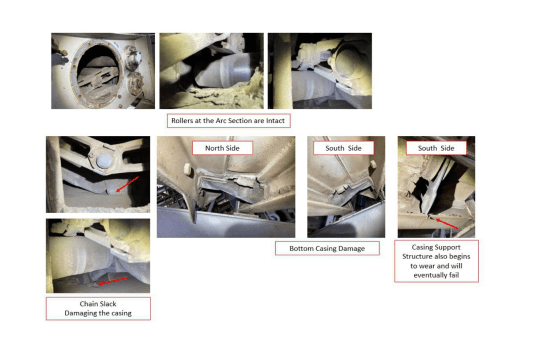

Before November 12, the Unit 1 DBA experienced elongation issues on its main bucket chain, which caused the chain to touch and cut the bottom casing. This problem is considered high risk and high impact on the operation. If not addressed immediately, this would cause a stuck-up of the DBA, or worse it could break the main bucket chain that can result in load deration (150 MW).

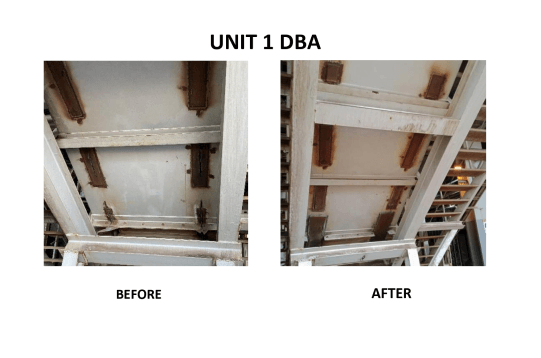

The Maintenance, Engineering, and Operating departments collaborated to address the issue and conducted proactive maintenance. Operating gave the Boiler Mechanical Team a window of 33 hours as per schedule to finish the repair.

The Boiler Mechanical Team then strategized the schedule, resources, and execution of activities. Mechanical Supervisor Jude Beldad coordinated with Operating, arranged the manpower resources and spare parts, monitored the activities, and updated the management regarding the status of the repair. Mechanical Technician Herson Hipolito executed the activities safely and properly as per the agreed strategy and schedule of repair. With the support of another Mechanical Technician, Edwin Duarte, and the Workshop team, they completed the repair within 22 hours, 11 hours ahead of planned. Afterward, the DBA was tested and monitored, and there was no reoccurrence of the elongation problem.

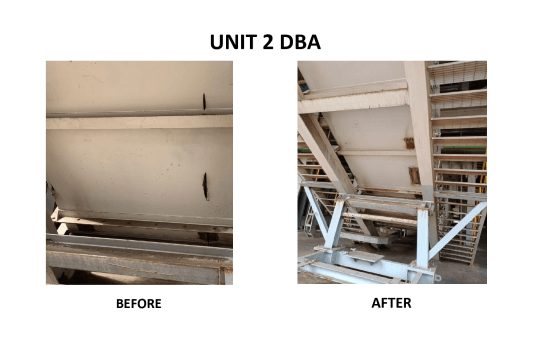

Unit 2 DBA had the same elongation problem. The same with Unit 1, there was also a possibility of DBA stuck-up or breaking of the main bucket chain, which could also result in a 150 MW load deration. However, unlike in Unit 1, due to the condition of the main bucket chain, the Engineering department recommended replacing it.

With that, the Boiler Mechanical Team again made the same preparations for Unit 2, but this time they strategized the replacement of the main bucket chain segment by segment. Beldad again led the coordination with Operating, as well as the monitoring and arrangement of activities, manpower resources, and spare parts. He updated the management once more with the status of the replacement.

Hipolito was the assigned technician once more, and the Boiler Mechanical Team completed the job within 19 hours, again ahead of the planned schedule of 33 hours. Mechanical Technician Joselito Baluyot and the Workshop team helped with the replacement. The DBA was tested and monitored and there has been no reoccurrence of the elongation problem as well.

The repair of Unit 1 and the DBA replacement in Unit 2 gave the company an estimate of Php13 million in savings for having no deration. With the high competence of the team, they proved that the repair and replacement activities can be done while the units are online.